See our most recent article published in The American Oil & Gas Reporter regarding wet sand delivery! The wet sand delivery method is taking our industry in the right direction toward reduction of costs, emissions and more. Read by clicking the link.

Let's be Honest

Liberty Energy’s Chairman and CEO, Chris Wright, weighs in on deceptive tactics in naming and describing climate and energy. In this 10 minute YouTube video link, Let’s be honest. you will hear Chris describe five commonly used tags around Energy and Climate that are both deceptive and destructive: climate crisis, energy transition, carbon pollution, clean energy, and dirty energy.

NSI TECHNOLOGIES WED(NSI)DAY LIVE TOPICS: THE LAST MILE IS ALL WET

Watch the full presentation

About

Kevin’s presentation titled Frac Sand Logistics – The Last Mile is ALL WET will discuss the evolution and existing options for proppant handling compared with a new method of wet sand handling which may provide significant benefits over the current industry standard.

The amount of frac sand consumed by a single horizontal well now averages approximately 13 million pounds. Prior to pumping the sand into a well, it must be mined, washed, sieved, stored, and then transported to the wellsite before transfer into a frac blender.

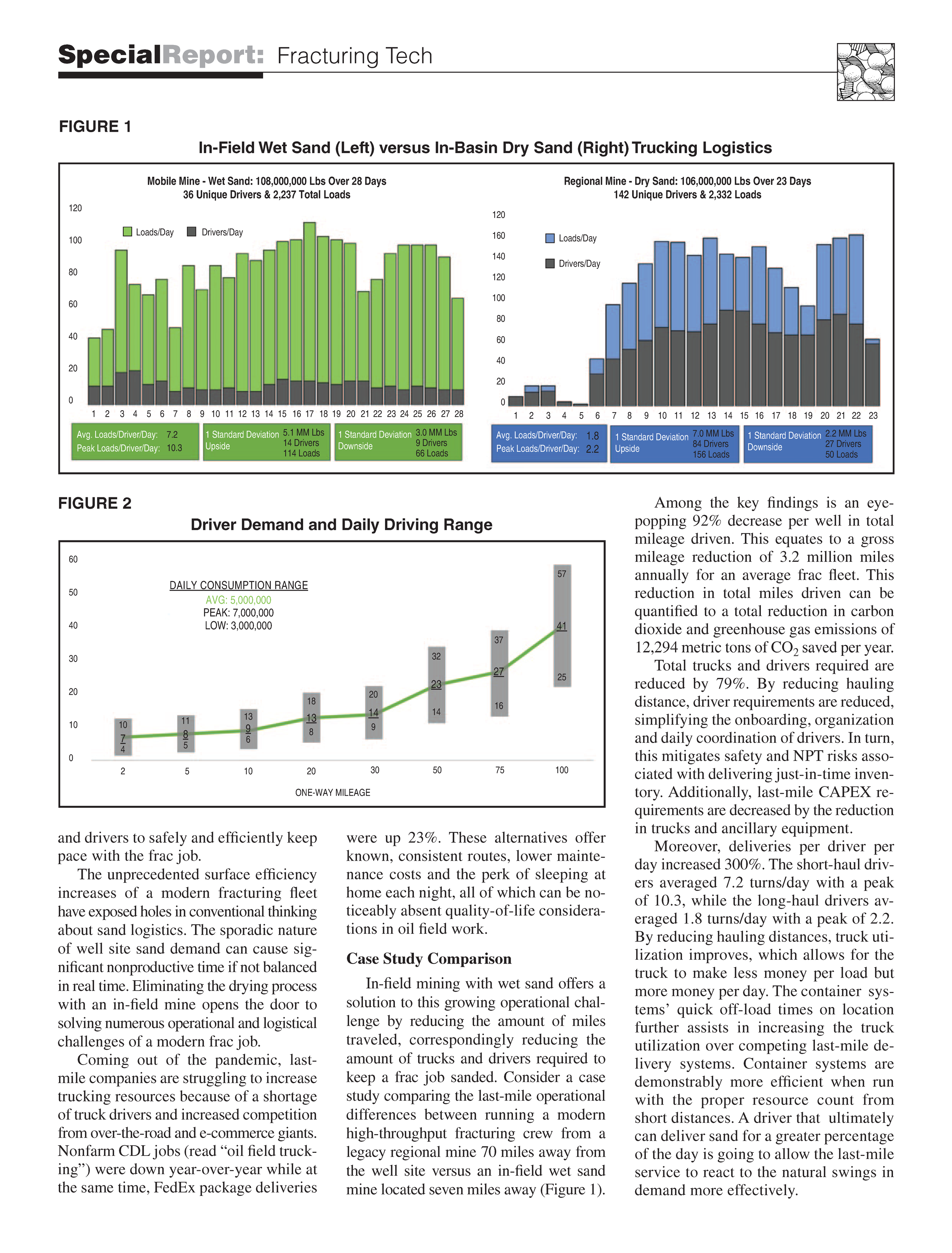

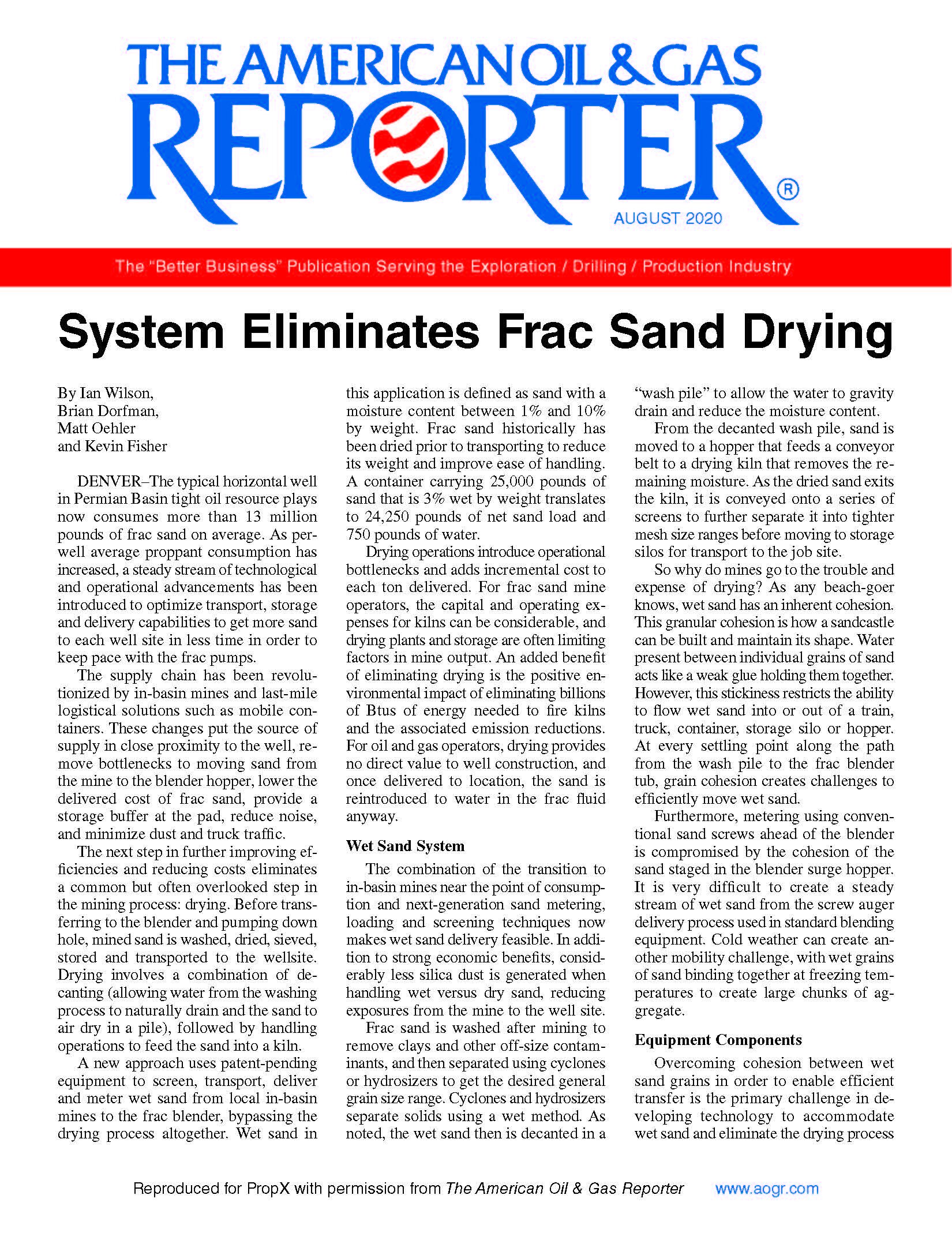

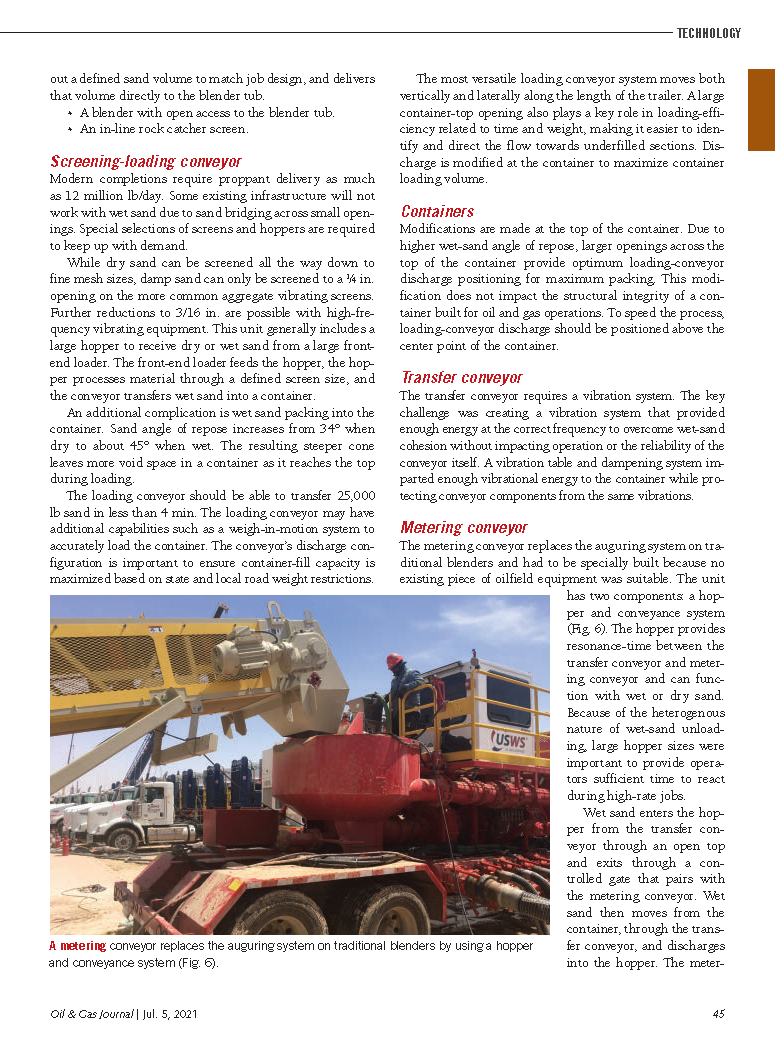

Today’s improved last mile logistics systems including silos and mobile containers have lowered the cost of delivery to the wellsite, provided for a sand storage buffer at the well, improved daily sand throughput as well as reducing noise, dust and truck traffic associated with the delivery. The sand drying process after washing at an in-basin sand mine involves a combination of decanting (allowing the sand to naturally drain and air dry in a pile) followed by handling operations to feed that sand into a natural gas fired dryer. The capital expenditure for installing a drying kiln plus the ongoing operating expense for a drying plant can be considerable. In addition, the drying process and dry storage capacity are often limiting factors with mine output and the drying process also contributes to an operation’s lifecycle CO2 and NOX emissions.

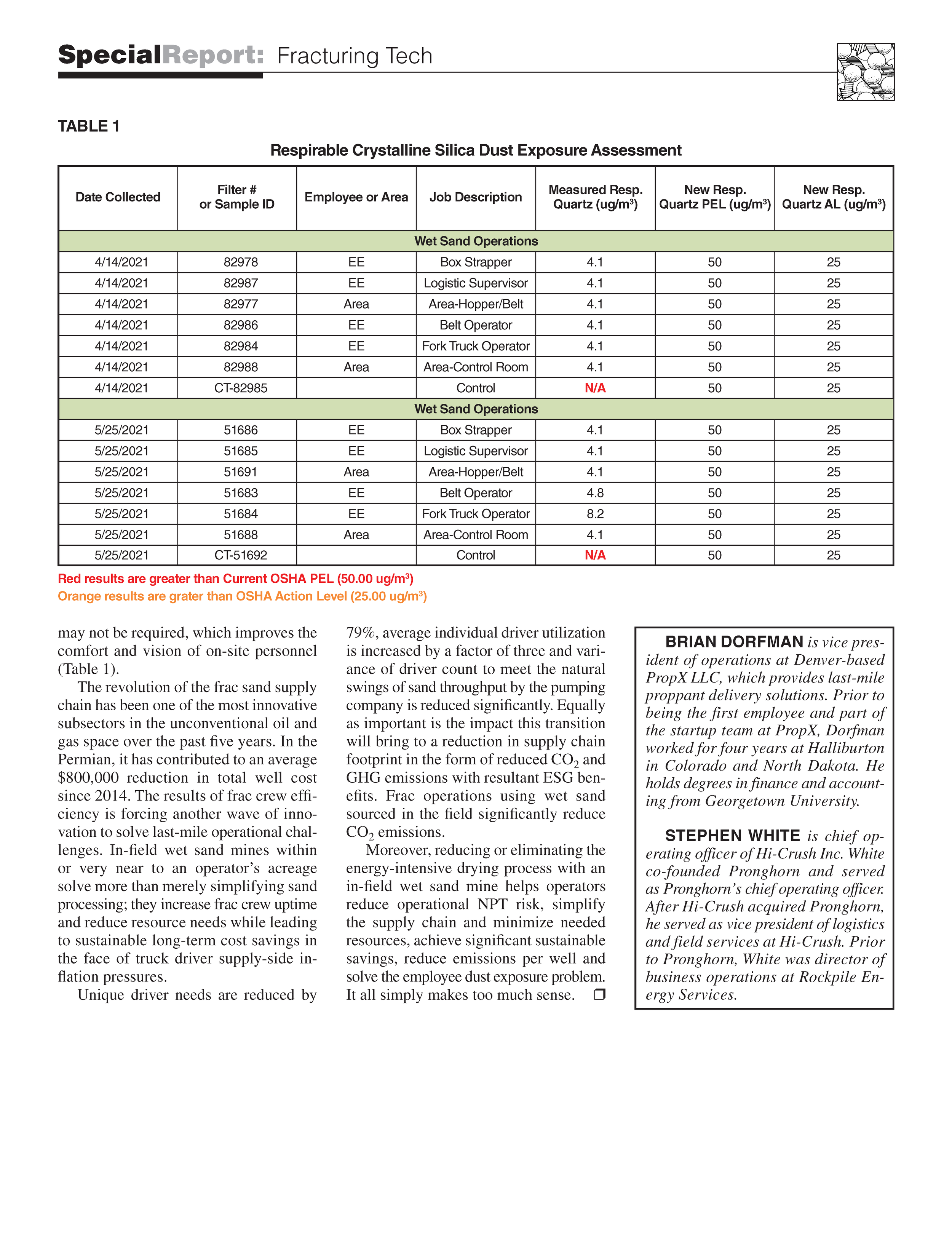

A new method has been introduced using patented equipment to screen, transport, deliver and meter wet sand from local mines to the frac blender, bypassing the drying process altogether. Wet sand in this application is defined as sand with a moisture content between 1% and 10% by weight. Operational results and benefits are compared to the current industry standard of delivering sand with a negligible moisture content.

PropX Acquired by Liberty Oilfield Services!

PropX, the last word in last mile logistics for the oilpatch, is excited to announce that we have been acquired by Liberty Oilfield Services (NYSE: LBRT)

This combination will enable PropX to enhance our equipment development as well as our logistics data, software and technology, offering the industry an unparalleled last-mile solution of equipment, software and frac experience.

Founded in 2016, PropX is a leading provider of last-mile proppant delivery solutions including proppant handling equipment, logistics and software across North America. PropX offers innovative environmentally friendly technology with optimized dry and wet sand containers plus wellsite conveying equipment that drive logistics efficiency while reducing truck traffic, noise and emissions. PropX wet sand handling technology is a key enabler of the next step of cost and emissions reductions in the proppant industry. PropX also offers customers the latest real-time logistics software, PropConnect. PropX will continue to provide our excellent service and support in delivering these solutions to all of our clients industry-wide.

“From our inception, PropX set out to provide the best solution for delivering proppants from a terminal or mine to the wellsite and into a service company blender on hydraulic fracturing operations. With services and equipment supplied across all major tight oil and gas basins across the US, PropX has built a reputation for customer service and innovation on more than a quarter of current frac operations. Our latest system for delivery of wet sand has changed the way our customers think about sand supply and the benefits of lower cost, reduced trucking, eliminating emissions from sand drying and reducing truck trips which have been touted by customers ranging from frac companies, E&P’s and sand suppliers. These wet systems provide substantial ESG benefits to our clients” said Kevin Fisher, CEO of PropX.

“This combination will allow PropX to continue to efficiently develop our hardware solutions, automating processes to streamline ordering, delivery, inventory tracking and invoicing in the last mile and those developments will benefit all of our clients: frac service providers, E&P customers, sand mining and trucking carriers alike. With rising demand for oil and gas along with the services required to fulfill that demand, the future has never been brighter. We look forward to this combination of innovative companies.”

Click HERE to read the press release from Liberty

Localizing last mile with mini-mines & wet sand operations directly affects and improves last mile efficiency

Localizing last mile with mini-mines & wet sand operations directly affects and improves last mile efficiency. In this case study, we found:

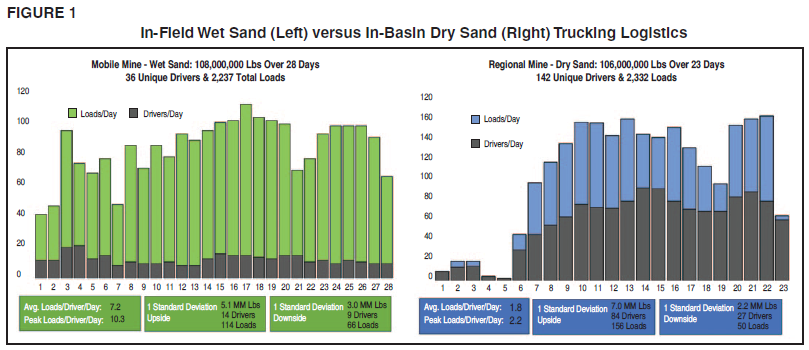

Figure 1: Mini mine with wet sand from 7 miles away (left) & regional mine with dry sand from 70 miles away (right)

Decrease in total mileage driven by 92%

Total truck requirement is reduced by 79%

Deliveries/driver/day increased by 300%.

Total boxes needed for the job decreased by 48%

CO2e from sand drying & last mile trucking combined decreased by 95%.

To read the full article click the button below or visit AOGR HERE to access the digital magazine

OGJ- WET SAND IMPROVES PERMIAN BASIN SUPPLY CHAIN

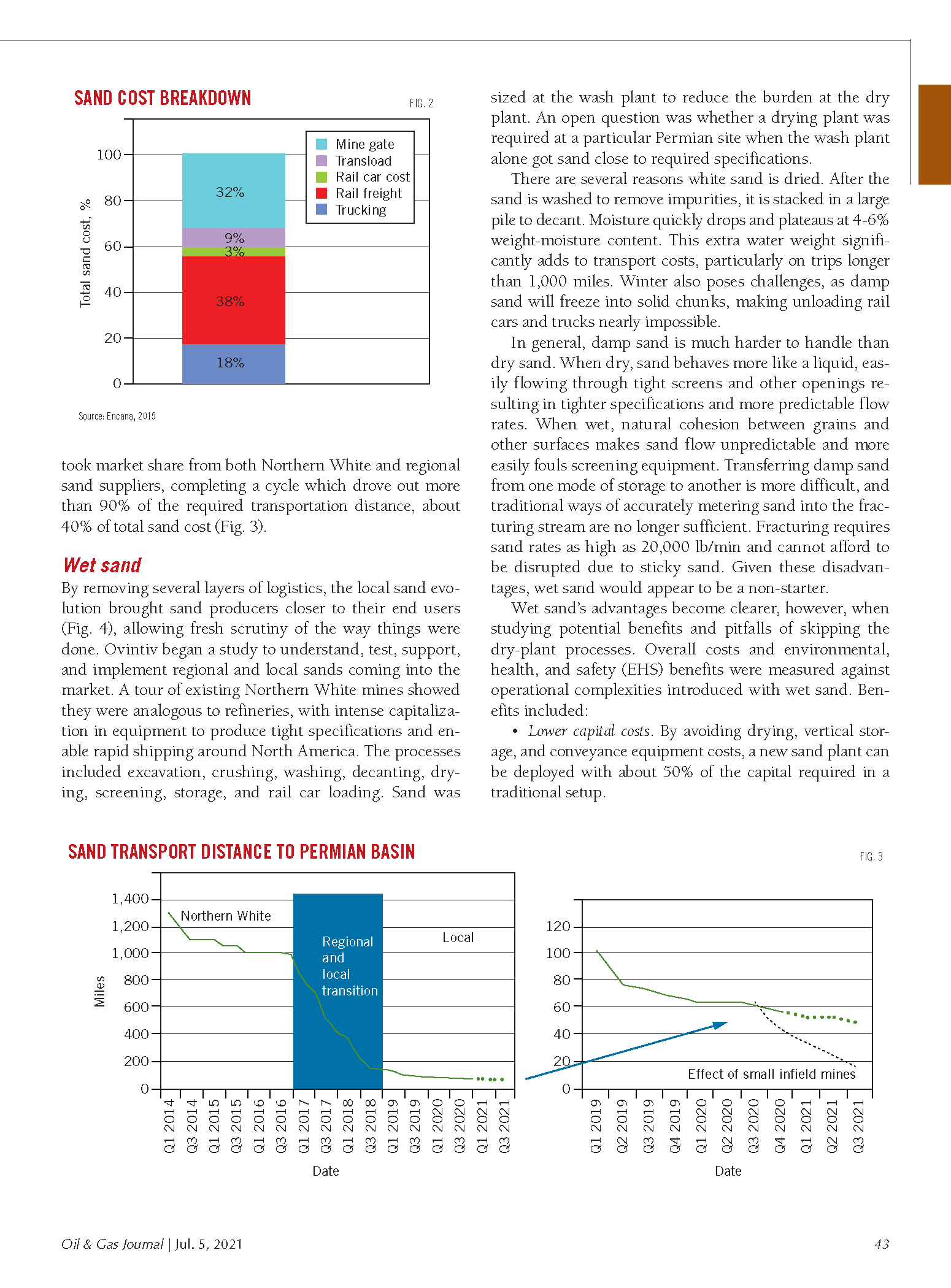

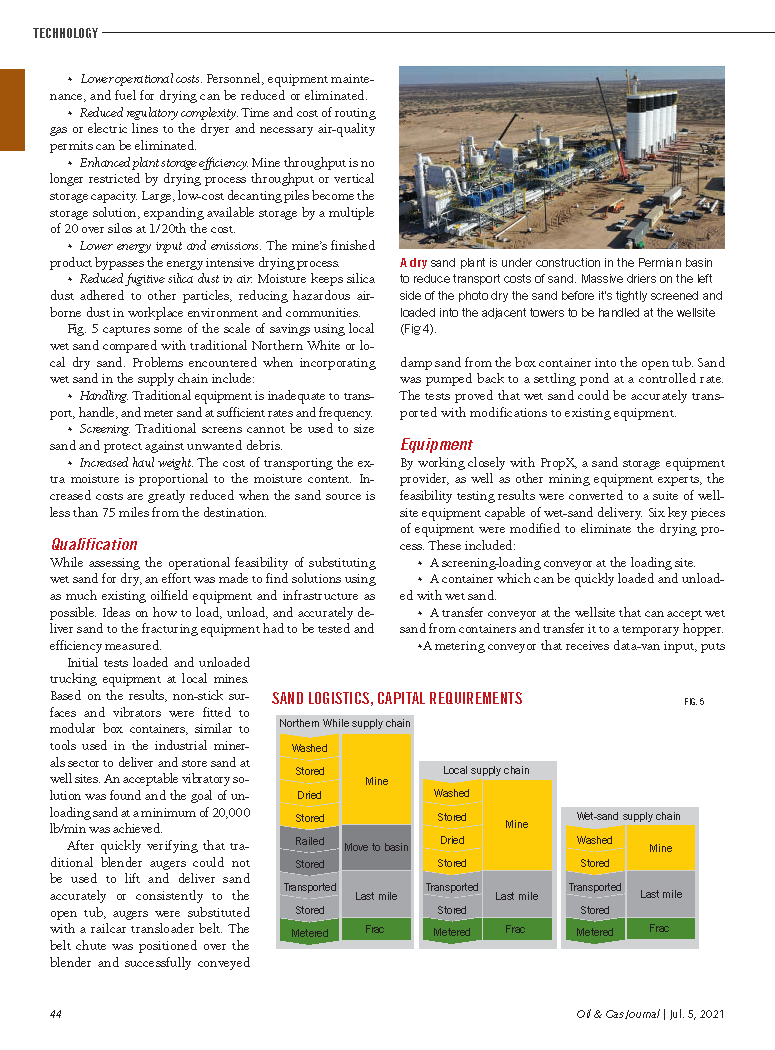

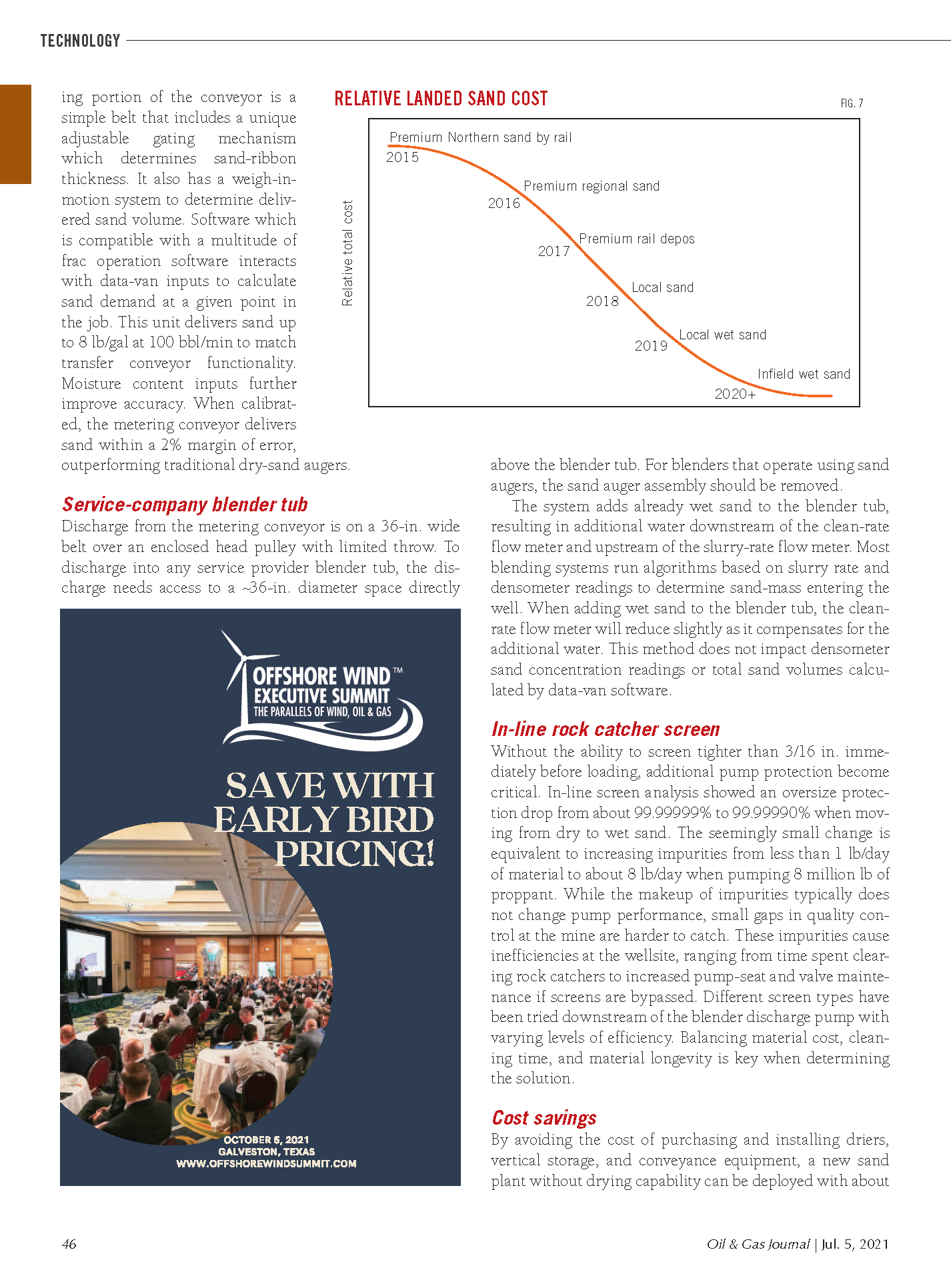

We are pleased to share a well written article by our friends over at Ovintiv written in the Oil &Gas Journal in July. The article lays out how wet sand has and will continue to improve their Permian Basin supply chain’s operation & sustainably reduce cost. “Relative to Northern White imports, in-field wet sand mines remove about 66% of total sand cost, permanently reducing per well costs by more than $800,000 over the last 5 years.”

Want to access the full Oil & Gas Journal Volume 119, Issue 7? Click here

PropX's Brian Dorfman Honoree of E&P's 40 Under Forty

A big congratulations to Brian Dorfman for being honored as one of E&P Plus’s 40 under Forty. At just 30 years of age, Brian has accomplished a great deal- from playing a pivotal role in the development and launch of PropX to his countless contributions to the company and the industry. Brian Dorfman is PropX’s Vice President of Operations and was PropX’s 1st employee, coming to us with a background in sales and operations.

Among the many other accomplishments Brian has achieved in his work career thus far, he is also an inventor on a growing list of patents for last mile frac sand equipment, was a primary author, and delivered an SPE paper as presenting author of SPE #199975 on a wet sand motive system at the Calgary Unconventional Resources Conference in 2020, has written or co-written several technical articles for the American Oil and Gas Reporter and is a recognized industry expert in last mile logistics and equipment.

Click the Button Below to read Brian’s full 40 Under Forty profile

PropX Featured in JPT: Just Add Water: Why US Shale’s Next Big Supply-Chain Revolution Is Wet Sand

In September, PropX’s very own Brian Dorfman presented SPE 199975 Can Wet Sand be Used for more than Building Sand Castles on the Beach? by B. Dorfman, M. Oehler, and K. Fisher, PropX; I. Wilson, EnCana Corporation, Ovintiv. This Case study reviewed the teamwork of PropX & Ovintiv over the last year putting the Wet Sand concept to test in the field.

We are honored to be featured in the Journal of Petroleum Technology in this article written by Trent Jacobs, who dives into what we are now seeing since the completion of the studied field tests.

Want to know more about Wet Sand? Contact us today or CLICK HERE for our downloadable Wet Sand Flyers

January 2021 E&P plus: Cut Frac Sand Cost, Improve Your ESG Score

AOGR Special Report: System Eliminates Frac Sand Drying

This article from the August 2020 issue of The American Oil and Gas Reporter highlights the latest innovation from PropX – an innovative and patent pending last mile frac sand logistics system designed to deliver wet or dry sand from the sand source to the frac blender. More than 1 billion pounds of wet sand have been delivered with this technology. The benefits of delivering wet sand are many: lower cost, substantially less energy required and lower emissions due to eliminating the drying process, eliminates silica dust, removes substantial capital investment needed at a minesite, reduces makeup water consumption at wellsite among other benefits.

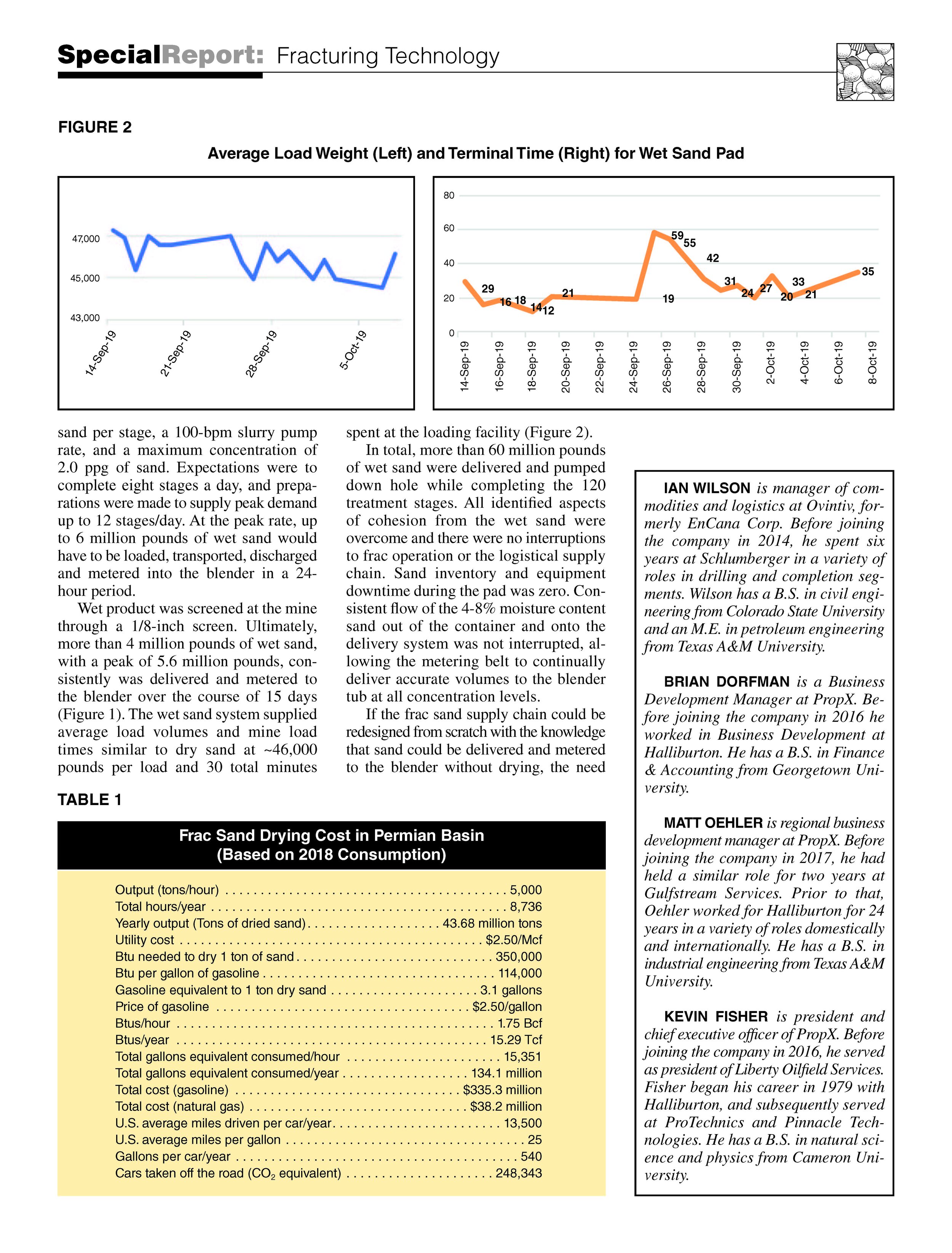

Let's Talk About Throughput

PropX throughput statistics indicate 13.4 Million lbs of sand delivered and pumped in 24 hours, a new efficiency record as well as daily counts where our clients have demonstrated the ability to surge offloading above 12 trucks per hour while keeping the same small total footprint

Press Release: Proppant Express Investments Prevails in U.S. Court of Appeals for Federal Circuit

PropX is a Key Instrument in the Wet Sand Symphony

Wet Sand Direct To Blender Might Be Music To Our Fracing Ears

This Infill Thinking guest contribution was co-authored by Brian Dorfman, Matt Oehler and Kevin Fisher, of PropX.

April 10, 2020

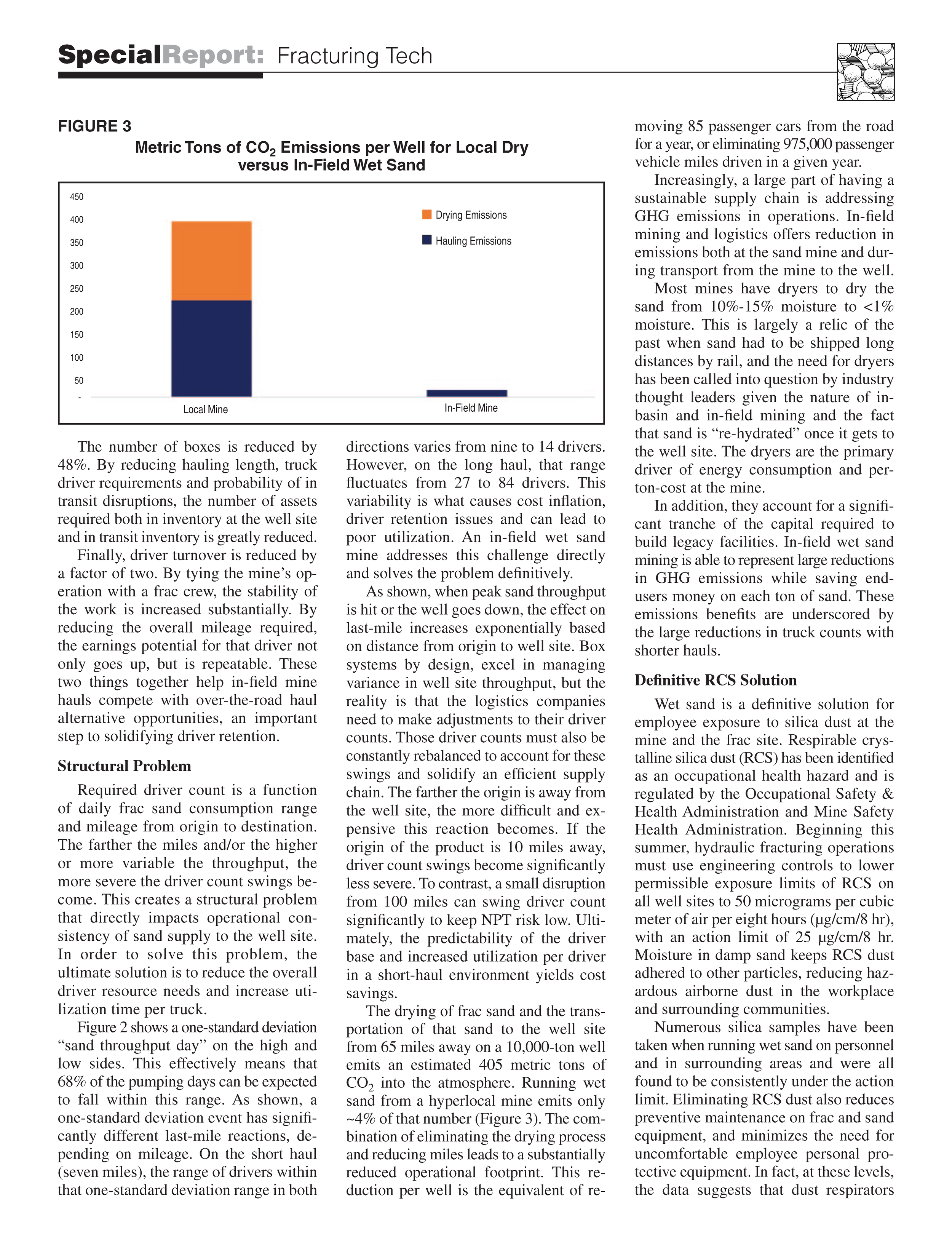

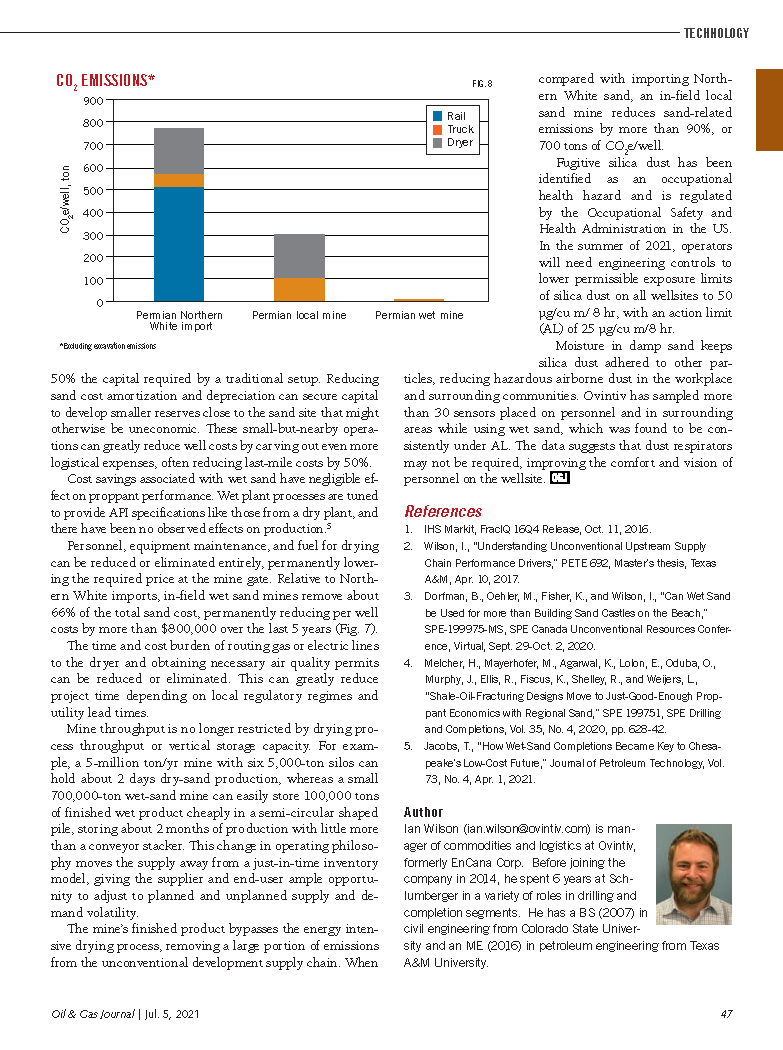

In addition to the personnel exposure benefit, the elimination of the drying process has a very real impact on energy consumption and the resulting emissions. Converting an annual operation that pumps 360,000 tons of sand dried by natural gas to a wet sand operation would reduce CO2 emissions by at an estimated 6,230 – 8,280 tons per year.

This emissions reduction is the equivalent of removing 2,040 cars off the road for a year. That’s for only one average frac operation! Convert just 10% of just the Permian market to operating with wet sand and the emissions reduction is equivalent to removing 25,000 cars from the road annually. That’s worth bragging about…

Infill Thinking is a subscription-based online publication focused on oil and gas. In order to continue reading this article you will need to subscribe to Infill Thinking by clicking the button below

Denver Business Journal Executive Voice: Oil industry vet builds sandboxes that changed fracking

PropX Prevails in Patent Trial and Appeal Board Ruling Resulting in Invalidation of SandBox Logistics Patent Claims

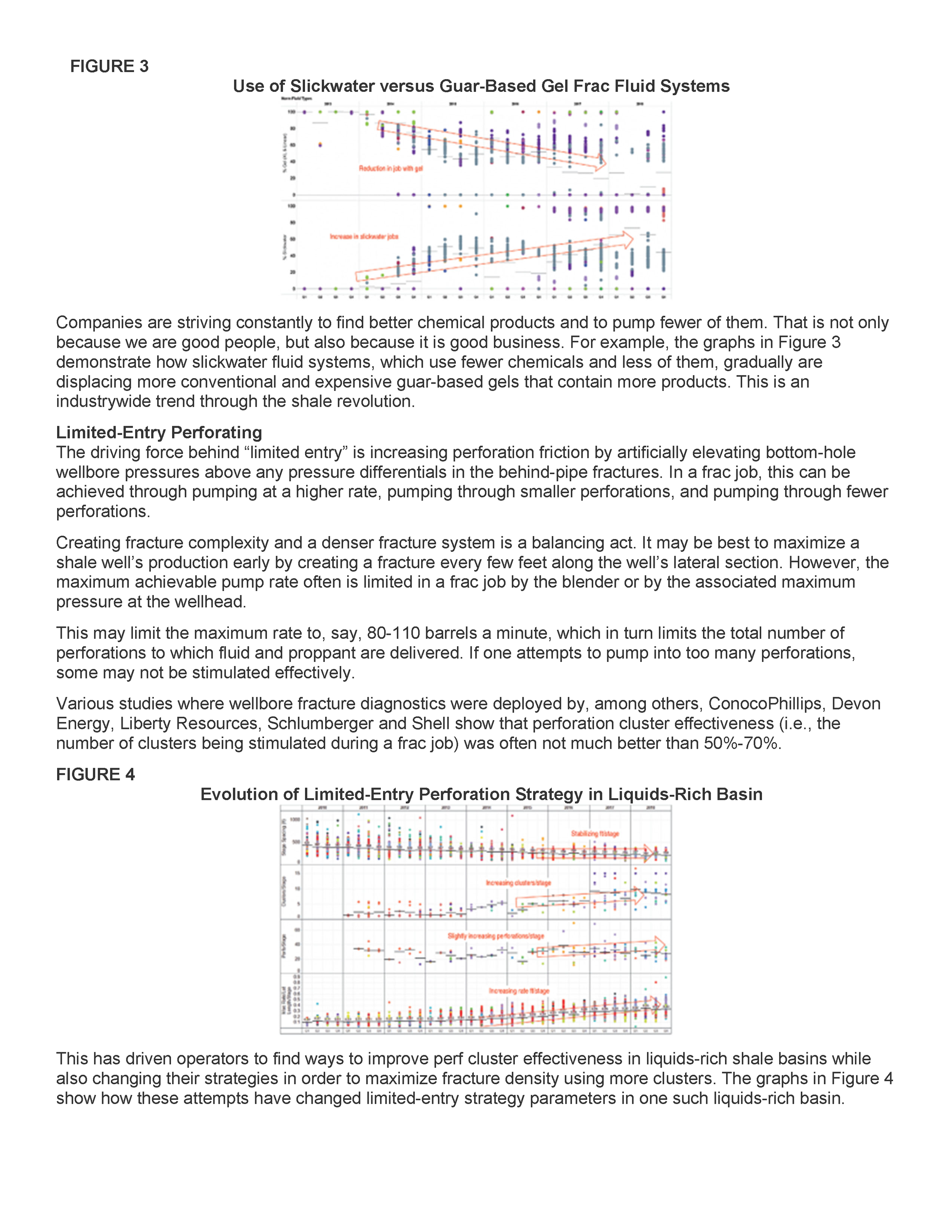

Kevin Fisher co-author of AOGR's August Issue- Discusses Hydraulic Fracturing Trends

Did you miss the Streamed PropX Presentation at EnerCom? Watch it NOW!

During the 24th Annual Oil & Gas Conference held by EnerCom, our CEO & President Kevin Fisher, spoke on the Sand Panel. His presentation was streamed live for everyone to view, but don’t worry if you missed you can watch it here!

During this Sand Panel Kevin digs into the challenges our industry faces in the last mile as well as discussing the rapid changes happening in sand logistics.

Most importantly Kevin discusses the history of PropX and how it is hands down the best solution in the changing landscape of the last mile.

PRESS PLAY TO WATCH NOW!

Video not loading? Click the button below!

PRESS RELEASE: Proppant Express Investments Prevails Again by Invalidating 24 SandBox Logistics Patent Claims

DUG PERMIAN: Kevin Fisher Speaker on Last Mile Perspectives Panel

PropX is excited to Annouce that Kevin Fisher, our CEO & President will be a speaker on the Last Mile Perspectives Panel at this years DUG Permian Basin Conference.

The Conference takes place at the Fort Worth Convention Center on April 15th-17th 2019

Panel: Last Mile Perspectives

Labor shortages, regulatory issues, and capital efficiency call for new solutions in proppant delivery. Two experts discuss the specifics of evolving technology in last mile delivery.

SPEAKER(S):

Kevin Fisher, CEO, PropX

Solaris Oilfield Infrastructure, TBA